What if manufacturers could get machine builders to deliver a new production line where the industrial Ethernet managed switches were configured exactly to manufacturing network and security specifications with faster commissioning times. No more unmanaged switches or misconfigured vulnerable machine networks that may misbehave once they are integrated into the manufacturer’s network creating costly downtime.

The Cisco Industrial Network Director (IND) plug and play solution makes it possible and without the need for networking experts. The controls team and security experts at the manufacturer use the Cisco Industrial Network Director graphical user interface to define company approved configuration and firmware version in a plug and play profile.

This profile can then export and made available to the machine builder or OEM. Once the machine builder imports this profile into their local instance of the Industrial Network Director, they simply power up the Cisco Industrial Ethernet switches and assign a dynamic or static IP address to them.

The plug and play agent in the switches connects to the local instance of the Industrial Network Director which allows the automation engineers to select the switches on the graphical user interface and assign them with the plug and play profile specified by the manufacturer.

The plug and play profile then automatically commissions the switches with the desired configuration and specified firmware version, allowing the machine network to be fully provisioned and operational in just a few minutes.

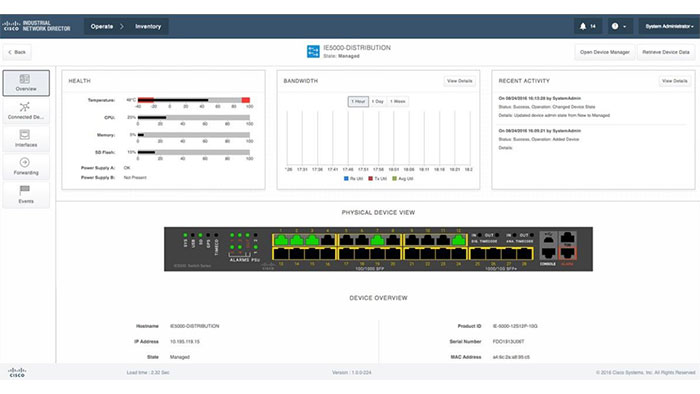

When the machine is shipped to the manufacturing plant and integrated with the onsite process network, local plant technicians can use this Cisco Industrial Network Director to monitor and troubleshoot the industrial network. In the event of a device failure, the SD memory feature in Cisco Industrial Ethernet switches allows for rapid device replacement.

If no SD card is available, the plug and play solution can detect the replay switch and automatically commission it with the previous configuration and software image dramatically reducing network downtime while protecting intellectual property and production integrity.

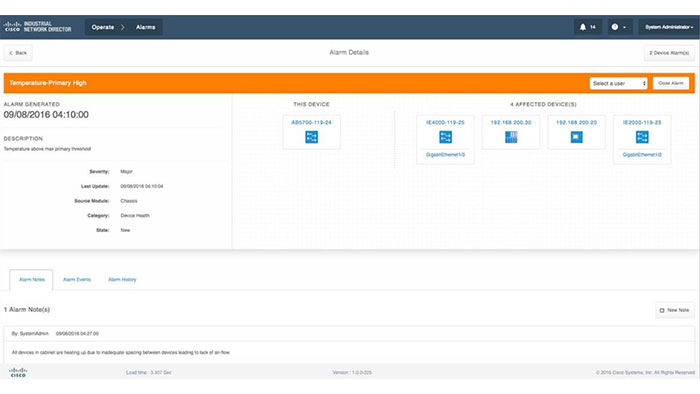

Finally, the system provides comprehensive alarm management features with real-time alerting of network events and reporting of effects to automation assets, allowing the operations and plant-IT team to consume network changes in context of the industrial process to simplify troubleshooting issue.

The following industrial switches are supported on this platform:

About this platform, currently, both Cisco’s traditional and smart licensing are supported. In traditional way, customers should use the PAKs to register all product instances while in Cisco Smart license, all instances would be registered and activated after connecting to Cisco smart software manager website.